Solved Problems

✔ Reducing operating costs

✔ Ensuring speed and accuracy of delivery

✔ Integration with production accounting

✔ Company’s internal control system

✔ Flexibility in package identification

✔ Simplified and faster inventory management

Our advanced technology for barcode scanning, package weighing and labelling helps optimise accounting quality control. Accounting quality control is an important process for auditing, monitoring efficiency and preventing errors.

Manual barcode scanning is a slow, labour-intensive process that can be done incorrectly due to missed products, mixed packaging and misdirected pallets. Such mistakes can lead to serious consequences such as loss of profits, fines or even legal action.

With this technology, operators receive a mismatch error when they start working with the wrong package and cannot continue working without correcting the error. Forklift drivers no longer need to scan packages manually, they can receive immediate feedback to send the product and pallets to the right truck. Shipments can leave the warehouse faster.

With 5-10 trucks dispatched per day, our system pays for itself in one year, saving 25 minutes of handling time per truck.

✔ Reducing operating costs

✔ Ensuring speed and accuracy of delivery

✔ Integration with production accounting

✔ Company’s internal control system

✔ Flexibility in package identification

✔ Simplified and faster inventory management

Industrial video camera reads one-dimensional 1D, two-dimensional 2D codes and RFID codes. The collected information is transmitted to the controller.

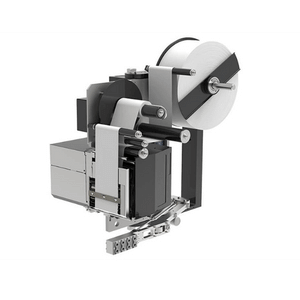

The barcode of the package is linked to its weight and sent via the controller to the server for further accounting. After scanning the data, the label is formed and applied by the Print and Apply device.

Data is automatically imported into the accounting system (supported interfaces: Database, Rest API, Mqtt, AWS IOT and Azure IOT).

Automated systems are significantly more productive than manual work.

Automation reduces the likelihood of human error, which can be caused by fatigue or monotonous work.

Optimising quality control ensures that standards are consistently met, as its software operates within defined parameters.